| |

|

|

|

Manufacturing subsidiary "Techno-Eye CO.,LTD."

Corporate Profile

| Techno-Eye CO.,LTD. |

| Establishment |

1981 |

| Executive |

Shinji Suda, President |

| Capital |

JPY 48,000,000 |

Established as a manufacturing subsidiary of DAICO MFG CO., LTD.

Operation Bases

| Head Office |

|

676 Kuze Nakahisa-cho, Minami-ku, Kyoto, 601-8207 Japan

TEL: +81 75-921-7251 FAX: +81 75-922-4411

|

| Kuze Plant |

Address |

676 Kuze Nakahisa-cho, Minami-ku, Kyoto, 601-8207 Japan

TEL: +81 75-921-7251 FAX: +81 75-922-4411 |

| Outline |

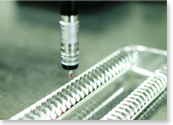

Made-to-order production of glass products in the fields of electronics and environmental energy on the basis of flame processing. |

| Yodo Plant |

Address |

231-17 Yodohon-machi, Fushimi-ku, Kyoto, 613-0903 JAPAN

TEL: +81 75-633-2211 FAX: +81 75-633-2212 |

| Outline |

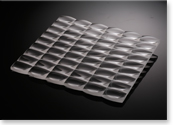

Made-to-order production of glass products in the fields of optics, life science and displays by combining several technologies such as polishing, optical bonding and film coating. |

| Arai Plant |

Address |

3-11 Kodan-cho, Myoko-shi, Niigata, 944-0020 Japan

TEL: +81 255-72-0757 FAX: +81 255-70-1138 |

Outline |

Made-to-order production of glass products in the fields of electronics and displays by using technologies of flaming, cutting and ultraprecision. |

Business Content

Semiconductor

| Semiconductors are key parts incorporated in products familiar to each of us including PCs, electric appliances, TVs and cell phones. Various “quartz glass” products are used to manufacture these semiconductors (IC and LSI). In the semiconductor field, we put various materials including quartz glass into commercial production by making the most of various processing methods such as cutting machines and flame burners. These products are delivered to our customers through inspections and measurements by use of precise measurement testing equipment such as 3D coordinate measuring machines. Since many of these products require high precision, the expertise of experienced processing engineers is relied upon for flame-burner used processing. |

|

|

Physical and chemical analysis

| In the field of physical and chemical analysis, various materials existing in this world are analyzed and measured by a diverse array of methods to contribute to product development as well as production and R&D. In this analysis field, various glass products such as quartz glass products are widely used on-site. Quartz glass products are particularly essential to analysis and measurement under various environments such as high temperatures exceeding 1000°C, high pressure, chemicals such as strong acid and alkali, and extremely low tolerance to impurities. We process and manufacture these products and provide them to our customers in many advanced fields such as bio-related, medical, environmental measurement (including water, soil and air measurement) and new product research & development fields. Our custom-made products vary in size and product specifications and there are many products that are “the only one in the world.” The skills and expertise of experienced burner processing engineers also play a substantial role here. |

|

|

Optics

| Human beings have used “light” in various forms from long ago. This has not changed in modern times when light is widely used in various industrial fields. Even in semiconductor manufacturing stated above, there is an important process of using light which is called “exposure.” In modern industries, “light” is critical such as in processing and measurements by use of light from a laser beam. In the field of optics, many glass products are used due to light transmission properties and we process and manufacture optical glass products such as high-precision polishing products (windows, lenses, mirrors, and laser optical parts, etc.). In particular quartz glass can exhibit high properties to wide ranging light sources and wavelengths and offer high performance and quality among various glasses. We manufacture products by fully focusing on material selection, material molding and precision polishing processing mainly as to quartz glass and delivering those products through rigorous quality testing to various industrial fields. Precision accuracy is highly demanding and there are many products which require precision as high as one millimeter per tens of thousands. Our sophisticated processing technology and precision measurement technology are also utilized here. |

|

|

|

|

|

|